Tooth Form &

Tooth Set

Tooth Construction

As with a bi-metal blade design, there are advantages to differing tooth constructions. The carbide tipped tooth has carbide tips welded to a high strength alloy back. This results in a longer lasting, smoother cutting blade.

Tooth Form

The shape of the tooth’s cutting edge affects how efficiently the blade can cut through a piece of material while considering such factors as blade life, noise level, smoothness of cut and chip carrying capacity.

- Variable Positive – Variable tooth spacing and gullet capacity of this design reduces noise and vibration, while allowing faster cutting rates, long blade life and smooth cuts.

- Variable – A design with benefits similar to the variable positive form for use at slower cutting rates.

- Standard – A good general purpose blade design for a wide range of applications.

- Skip – The wide gullet design makes this blade suited for non-metallic applications such as wood, cork, plastics and composition materials.

- Hook – Similar in design to the Skip form, this high raker blade can be used for materials which produce a discontinuous chip (such as cast iron), as well as for non-metallic materials.

Tooth Set

The number of teeth and the angle at which they are offset is referred to as “tooth set.” Tooth set affects cutting efficiency and chip carrying ability.

- Raker – 3 tooth sequence with a uniform set angle (Left, Right, Straight). Modified Raker: 5 or 7 tooth sequence with a uniform set angle for greater cutting efficiency and smoother surface finish (Left, Right, Left, Right, Straight). The order of set teeth can vary by product.

Raker

Modified Raker - Vari-Raker – The tooth sequence is dependent on the tooth pitch and product family. Typically Vari-Raker set provides quiet, efficient cutting and a smooth finish with less burr.

- Alternate – Every tooth is set in an alternating sequence. Used for quick removal of material when finish is not critical.

- Wavy – Groups of teeth set to each side within the overall set pattern. The teeth have varying amounts of set in a controlled pattern. Wavy set is typically used with fine pitch products to reduce noise, vibration and burr when cutting thin, interrupted applications.

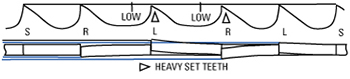

- Vari-Set – The tooth height / set pattern varies with product family and pitch. The teeth have varying set magnitudes and set angles, providing for quieter operation with reduced vibration. Vari-Set is efficient for difficult-tocut materials and larger cross sections.

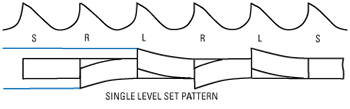

- Single Level Set – The blade geometry has a single tooth height dimension. Setting this geometry requires bending each tooth at the same position with the same amount of bend on each tooth.

- Dual Level Set – This blade geometry has variable tooth height dimensions. Setting this product requires bending each tooth to variable heights and set magnitudes in order to achieve multiple cutting planes.