Bandsaw Troubleshooting

| BLADE EFFECT | PROBABLE CAUSE | SOLUTION |

|---|---|---|

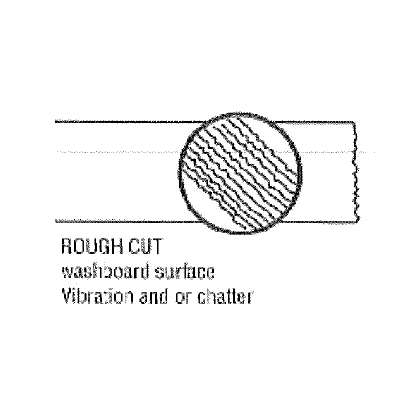

|

• Incorrect Blade

• Band tension too high • Excessive feed • Incorrect cutting fluid • Wheel diameter too small for blade width • Worn or chipped pressure block • Blade rubbing on wheel flange • Teeth in contact with work before starting sawing • Side guides too tight |

• Check tooth selection

• Reduce band tension, refer to operators manual • Reduce feed pressure • Check coolant recommendations • Use narrower blade • Replace worn pressure blocks • Adjust wheel alignment • Allow blade clearance above work • Refer to operators manual |

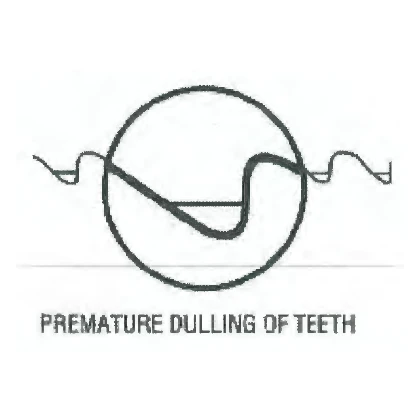

|

• Blade on machine backwards

• Improper blade break-in procedure • Hard material or heavy surface scale • Material is work hardening • Improper cutting fluid or mix ratio • Speed or feed too high |

• Install blade correctly

• Refer to recommended procedures • Check material hardness and surface condition • Increase feed pressure • Follow coolant mixing procedures • Check cutting recommendations |

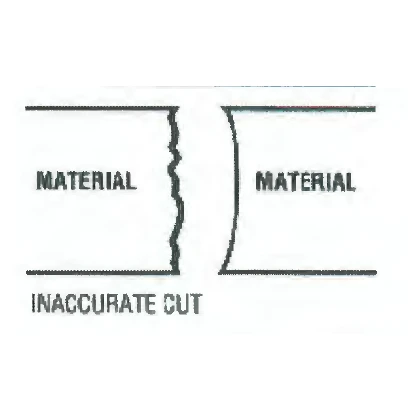

|

• Guide arms too far apart

• Blade worn out • Over or under feeding • Improper tooth pitch • Curing fluid not applied properly • Too many teeth for material cross-section • Guides worn or loose |

• Adjust guide arms closer to material

• Replace blade • Check cutting recommendations • Use proper tooth selection • Adjust coolant nozzles • Use proper tooth selection • Tighten or replace guides |

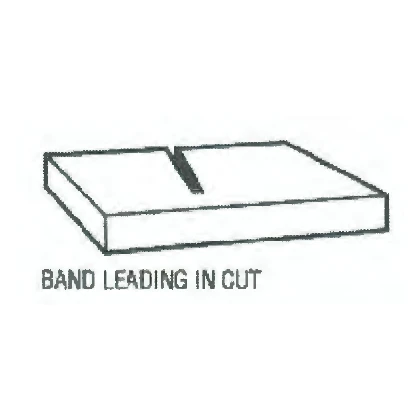

|

• Over feeding

• Low band tension • Tooth set damaged • Guide arms loose or space too wide |

• Check cutting recommendations

• Refer to operators manual • Check material hardness • Adjust guides and guide anns |

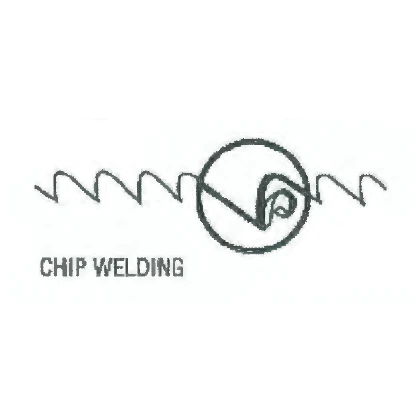

|

• Worn or missing chip brush

• Improper or lack of cutting fluid • Wrong coolant ratio • Excessive feed or speed • Incorrect blade pitch |

• Replace or adjust chip brush

• Check coolant flow and fluid type • Check coolant type and ratio • Reduce feed or speed • Use proper tooth selection |

|

• Indexing while blade in work

• Blade not high enough before index • Saw head drifts into work while neutral |

• Adjust index sequence

• Adjust height selector • Check hydraulic cylinder |

|

• Improper blade break-in procedure

• Speed too slow • Feed pressure to high • Tooth jammed in cut • Poor cutting fluid application or ratio • Hard material or heavy scale • Wrong blade pitch • Work spinning or loose nested bundles • Blade on backwards |

• Follow proper break-in procedure

• Refer to cutting recommendations • Reduce feed pressure • Do not enter new blade in that cut • Adjust coolant flow and ration • Check material or surface hardness • Use proper tooth selection • Tighten vices or use nesting clamps • Install blade correctly |

|

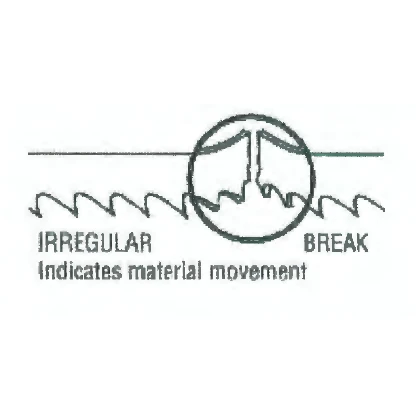

• Saw guides not properly adjusted

• Incorrect feed or speed • Incorrect blade • Material moved in vice |

• Align or adjust saw guides

• Refer to cutting recommendations • Use proper blade type and pitch • Inspect and adjust vices |

|

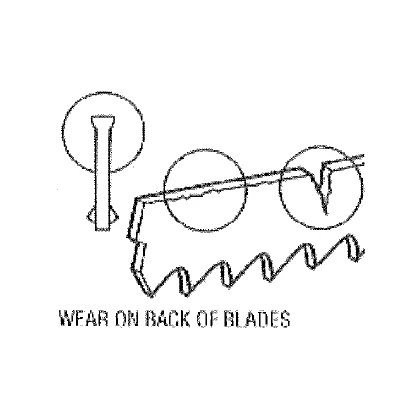

• Excessive back-up guide preload

• Low blade tension • Incorrect blade (carbon steel type) • Excessive feed rate or pressure • Damaged or worn pressure block • Guide arms spaced too far apart • Blade rubbing band wheel flanges |

• Adjust pressure blocks

• Refer to operators manual • Switch to a Bimetal blade • Reduce feed rate or pressure • Replace pressure block • Adjust guide arms closer to work • Adjust wheel alignment |

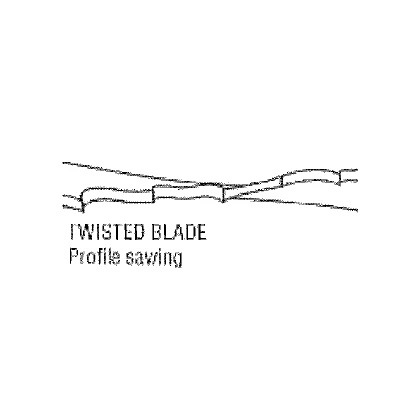

|

• Dull or damaged blade

• Incorrect feed or speed • Blade not supported properly • Low blade tension • Incorrect tooth pitch • Guide arms too far apart |

• Install new blade

• Refer to cutting recommendations • Adjust or tighten guide arms • Refer to operators manual • Use proper tooth selection • Adjust guide arms closer to material |

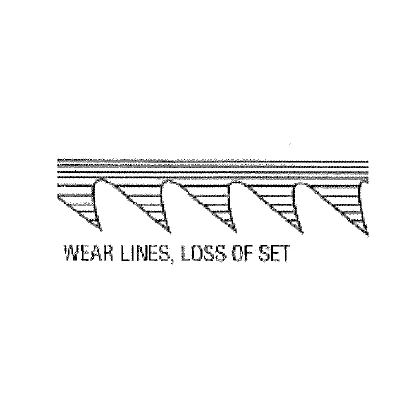

|

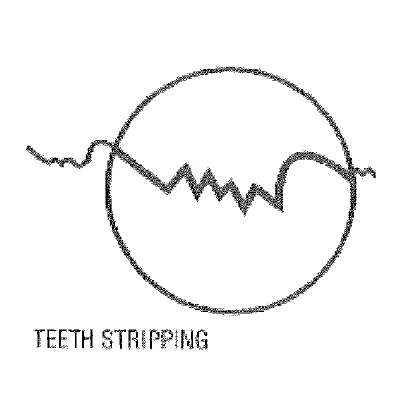

• Saw side guides too tight

• Blade riding too high in guide • Blade teeth riding on band wheel surface • Wrong blade width for machine • Chips be carried back into cut • Worn or damaged pressure block • Insufficient coolant flow |

• Adjust guides properly

• Adjust rollers or pressure blocks • Adjust tracking or replace wheel • Refer to operators manual • Replace or adjust chip brush • Replace pressure block • Adjust coolant flow |

|

• Blade binding in cut

• Side guides are too tight • Work loose in vice • Feed to heavy • Guide arms too far apart |

• Adjust feed or use heavy set blades

• Adjust guides • Adjust vices • Reduce feed pressure • Adjust guide arms closer to material |

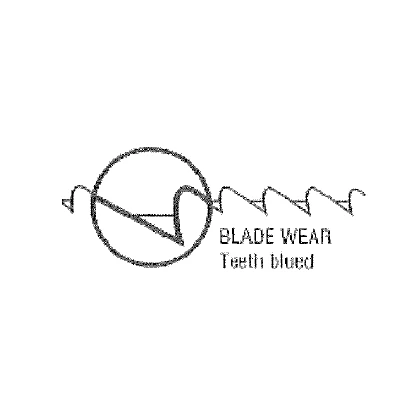

|

• Incorrect blade

• Heavy feed or too fast speed Lack of cutting fluid • Blade installed backwards |

• Use proper tooth selection

• Refer to cutting recommendations • Adjust coolant flow or ratio • Install blade correctly |

|

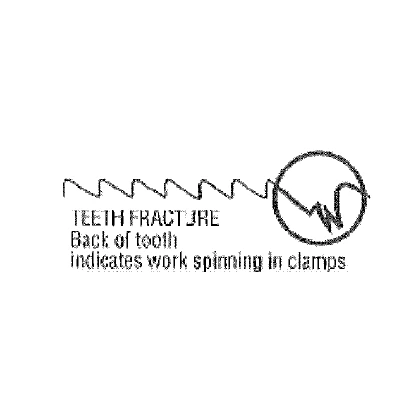

• Material loose in vice

• Incorrect tooth pitch • Feed too fast • Speed too fast |

• Adjust vices

• Use proper tooth selection • Reduce feed rate • Refer to cutting recommendations |